Low-voltage Directive correctly applied: These requirements result for your CE-compliant product

We take care of your CE marking along with accompanying measures.

You can affix the CE mark and sign the declaration of conformity without worries.

Willy Lebherz

Geschäftsführer easyCE GmbH

Declaration of conformity done!

Receive your CE declaration of conformity ready for signature.

Risk assessment completed!

CE mandatory risk analysis conducted.

Relevant directives & standards applied!

Your product evaluated against relevant directives and standards.

Technical documentation created!

Receive a pragmatic, user-friendly operating manual.

CE mark attached!

Simply affix the CE mark and you're done.

CE marking routines differ depending on your role

CE AS PRODUCER

Electrical equipment sold in the EU must bear the CE marking. Therefore, distributors wishing to place electronic products on the EU market must deal with the Low Voltage Directive (LVD). Manufacturers generally deal with questions such as: Which products are affected by this directive? What is the scope? Where ends the scope or. how is it linked to other policies and products outside the scope (such as military use)? How is the CE marking process defined in the Directive? What must be done under the Directive to ensure conformity?

The experts at easyCE will be happy to assist you in placing your product on the market in the EEA and in assessing special cases. We support you with CE, UKCA and other markings.

FAQ

What is the Low Voltage Directive?

The Low Voltage Directive is one of the oldest EU internal market directives on CE marking. The Low Voltage Directive (LVD) 2006/95/EG led designers to produce safe products, relying mainly on IEC (International Electro-technical Standards) and other technical standards.

The revised version of the Low Voltage Directive is 2014/35/EU dated 26 February 2014 and will apply from 20 April 2016. EU legislation requires that the applicable health and safety standards for electrical products placed on the EU internal market be uniform.

Products that meet the requirements of the Low Voltage Directive are provided with a CE marking to indicate conformity and approval in the European Community.

Which products fall within the scope of the Low Voltage Directive and need a CE mark?

Products must bear the CE marking according to the Low Voltage Directive if they are operated with low voltage and are placed on the European market

Unlike industrial, military and scientific applications where high voltage is often used, LVD is applied to electrical equipment that operates with an input or output voltage that is in the following range

- Between 50 and 1000 V for AC

- Between 75 and 1500 V for direct current

Low voltage is defined as the range between high voltage and low voltage. High voltage is over 1000 V for AC and at least 1500 V for DC, see below:

| Voltage range | AC voltage (V) | DC voltage (V) | Defining risk |

|---|---|---|---|

| High voltage | > 1 000 | > 1 500 | Risk of electric arc |

| Low voltage | 50 to 1 000 | 120 to 1 500 | Risk of electric shock |

| Extra-low voltage | < 50 | < 120 | Small risk |

For example, what types of products must bear a CE mark under the Low Voltage Directive?

The CE marking according to the Low Voltage Directive covers a wide range of electrical equipment for both private and professional use, such as

- AC adapters; such as adapters for laptops, mobile phones, printers, home appliances and travel adapters, etc.

- Electrical cables and wires; such as shielded, twisted, fiber optic, coaxial and ribbon cables, etc.

- Lighting products; such as LED, ceiling, stage, building exterior and vehicle lighting, etc.

- Household appliances; such as refrigerators, coffee makers, toasters, blenders, microwaves, electric cookers, vacuum cleaners and hair dryers, etc.

- Also, any replaceable part of household appliances and electrical components such as switchgear, ballasts, electric motors and generators must be compliant so that the final product still complies with the LVD for safety reasons.

- Audio and video equipment; such as amplifiers, projectors, light reflectors, microphones, DVD players and tape recorders, etc.

Which products are NOT covered by the Low Voltage Directive?

Devices developed by a manufacturer for their own home use do not have to bear the CE mark according to the Low Voltage Directive, but should meet the safety requirements of the Directive.

Excluded from the scope of the LVD are certain classes of electronic devices listed in Annex II to the Directive.

These product classes do not fall within the scope of the Low Voltage Directive, but are covered by other technical standards or regulations. These products include:

- Medical devices (medical products are also subject to CE marking, but not according to the Low Voltage Directive)

- Electricity meters,

- Railway or marine equipment,

- TV remotes and RC toys as well as electrical plugs and sockets for home use.

These products fall under either 50V ac or above 1000v ac and are therefore excluded from the LVD.

How are low voltage and high voltage generally defined?

Low voltage is defined as the range between high voltage and low voltage. High voltage is over 1000 V for AC and at least 1500 V for DC, see below:

| Voltage range | AC voltage (V) | DC voltage (V) | Defining risk |

|---|---|---|---|

| High voltage | > 1 000 | > 1 500 | Risk of electric arc |

| Low voltage | 50 to 1 000 | 120 to 1 500 | Risk of electric shock |

| Extra-low voltage | < 50 | < 120 | Small risk |

The Low Voltage Directive adopts the definitions of IEC standards for their applicability. The International Electrotechnical Commission (IEC) and its national counterparts (IET, IEEE, VDE, etc.)

To fully understand the scope of the Low Voltage Directive, some understanding of low and high voltage electrical products is required.

Low voltage or high voltage is a relative term in electrical engineering. It varies in relation to the risk arising from and connected to an electrical equipment. The risk associated with electrical equipment can be divided into three stages, namely:

- small risk

- electric shock

- electric arc

High voltage refers to an electrical potential large enough to cause injury or damage from electric arcs. The devices carrying high voltage ensure special safety requirements.

Low voltage circuits are defined by electrical safety regulations and are exempt from the safety precautions required for high voltage. However, these electrical safety regulations vary by country, regulation and other regulations.

What is the CE marking requirement?

CE marking is required for around 24 EU-regulated product groups, including construction products, gas appliances, toys, measuring instruments, machines, electrical equipment and lifts, etc.

The CE marking of products covered by the Low Voltage Directive is in some cases with additional markings such as WEEE-Marking or the Wheelmark symbol. On the European Commission’s website, you can find a list of product types that require CE marking.

What other directives and regulations must be considered in the CE marking and conformity assessment of electrical products?

Although the new low-voltage directive (2014/35/EU) is a "fully harmonized safety directive" as it covers all electrical risks and safety aspects there are nevertheless several directives that must be considered when CE marking electrical products. These include

- LVD (Low voltage directive),

- EMC (Electromagnetic Compatibility Directive),

- RoHS (Restriction of Hazardous Substances-Directive),

- Ecodesign Directive,

- Energy Labelling Directive,

- ATEX directive,

- WEEE (Waste Electrical and Electronic Equipment),

- Battery and Accumulator Directive.

There are several EU directives that require CE marking and each of these directives has its own specific requirements for the corresponding devices and therefore needs to be reviewed and applied accordingly. The CE marking indicates compliance with as many directives as applied at the time of the declaration of conformity. To determine which Directive(s) could be applicable(s), it is necessary to understand the requirements of an applicable harmonized standard for the product concerned. Harmonized standards can be identified by searching the "Official Journal" on the European Commission’s website.

How is the CE marking process defined in the Low Voltage Directive?

The Low Voltage Directive stipulates that electrical products must be provided with the CE marking. The Low Voltage Directive provides for a single way of conformity assessment. The conformity assessment must be carried out by the manufacturer or. placing the product on the market in order to be able to label the product with the CE mark:

- Manufacturer or distributor checks the product-specific requirements resulting from the directive

- The manufacturer or distributor then identifies further applicable directives and, above all, harmonized standards.

- The next step is to analyze whether a conformity assessment by a notified body is required.

- The product is tested for conformity.

- The required technical documentation is prepared and made available for documentation

- The CE marking is affixed and the EU declaration of conformity is issued.

Does the conformity assessment under the Low Voltage Directive have to be carried out by a notified body?

No, the new Low Voltage Directive does not require notified bodies to perform died conformity assessment for the CE marking. It is a process known as self-certification, in which the manufacturer is solely responsible for determining the conformity requirements and can carry them out.

What are the necessary legal consequences for the incorrect use of the CE marking?

CE marking can be incorrectly applied in two ways:

- First, CE marking is sometimes applied to products that do not meet legal requirements.

- Secondly, it is applied to products for which it is not necessary. For example, the E-mark is an EU mark for registered vehicles and vehicle parts sold in the EU and may not be otherwise identified. Similarly, the Maritime Equipment Directive (MED) requires the Wheelmark symbol and not the CE marking.

The competent authorities of the Member States, in cooperation with the European Commission, take control measures for the incorrect presentation of the CE marking. These measures range from fines to forced withdrawal of the product to imprisonment, depending on severity and local national legislation.

For example, in the United Kingdom, the misuse of the CE mark under Section 1 of the Trade Descriptions Act (1968 Trade Descriptions Act) is considered to be "Selling a product bearing a CE mark that is not so approved or outside the scope of the approval is a specific criminal offence."

What is the scope of the directive in relation to military products?

Due to national safety concerns, there are certain exceptions to the military-specific conformity requirements for CE marking, but the low voltage directive is no exception under EU law.

In the EU, military equipment is defined in a "list of 1958" and includes all military electronic devices, but offers no exception in itself. Only Article 346 of the TFEU provides a legal but limited exemption from EU market rules. An EC document states that this exemption under Article 346 must be carefully examined on a case-by-case basis and can only be carried out by the national authorities.

In addition, the Low Voltage Directive is one of the specific directives which are not exempt, as the European Commission declared on 23 April 2012 in relation to military equipment and ordered that equipment which falls within the scope of the radio and telecommunication terminal equipment that are subject to electromagnetic compatibility and the low-voltage directive, must be compliant and bear the CE marking.

How does the risk assessment for products covered by the Low Voltage Directive work?

There is no defined process for conducting a risk assessment for electrical equipment. However, it is a trend to apply a risk assessment in some of the recently updated, commonly applied but voluntary harmonized electrical safety standards, such as:

- EN60204-1 for the safety of electrical machines.

- EN 61010-1 for safety requirements for electrical measuring, control and laboratory equipment

The risk assessment as defined in the Machinery Directive is a good example of a process that can also be applied to electrical equipment.

Hundreds of companies trust easyCE

With easyCE, product compliance is really ‘easy’

Approach to CE marking

Type and manner of support

Scope of support

Contact during project processing

Find the easiest way to obtain the CE mark

Abbreviated process for CE derived directly from CE

All-inclusive or modular – whatever you prefer

Personal contact with experts who take your wishes into account

other CE service providers

Often lacking in sound judgement and unnecessarily complicated

Mostly flexible but often bureaucratic

Mostly flexible in terms of support scope

Mostly personal contact

CE Software

Follows standardised process; special circumstances not taken into account

Double burden for you: software management + no support during processing

Only according to software scope and purchased modules

No contact

You want support that lightens your workload and doesn't create more work.

This is what successful projects look like

Conformity assessment procedure and CE marking for an electric plate separator

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for a plate separator designed to separate liquid droplets from aerosols. Through the integration of a pressure regulating valve and electrical control components according to EN 60204-1, reliable operation with simultaneous intrinsic safety is ensured. The risk assessment according to EN ISO 12100 particularly addressed thermal hazards and monitoring of emergency operation behavior in case of signal loss.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

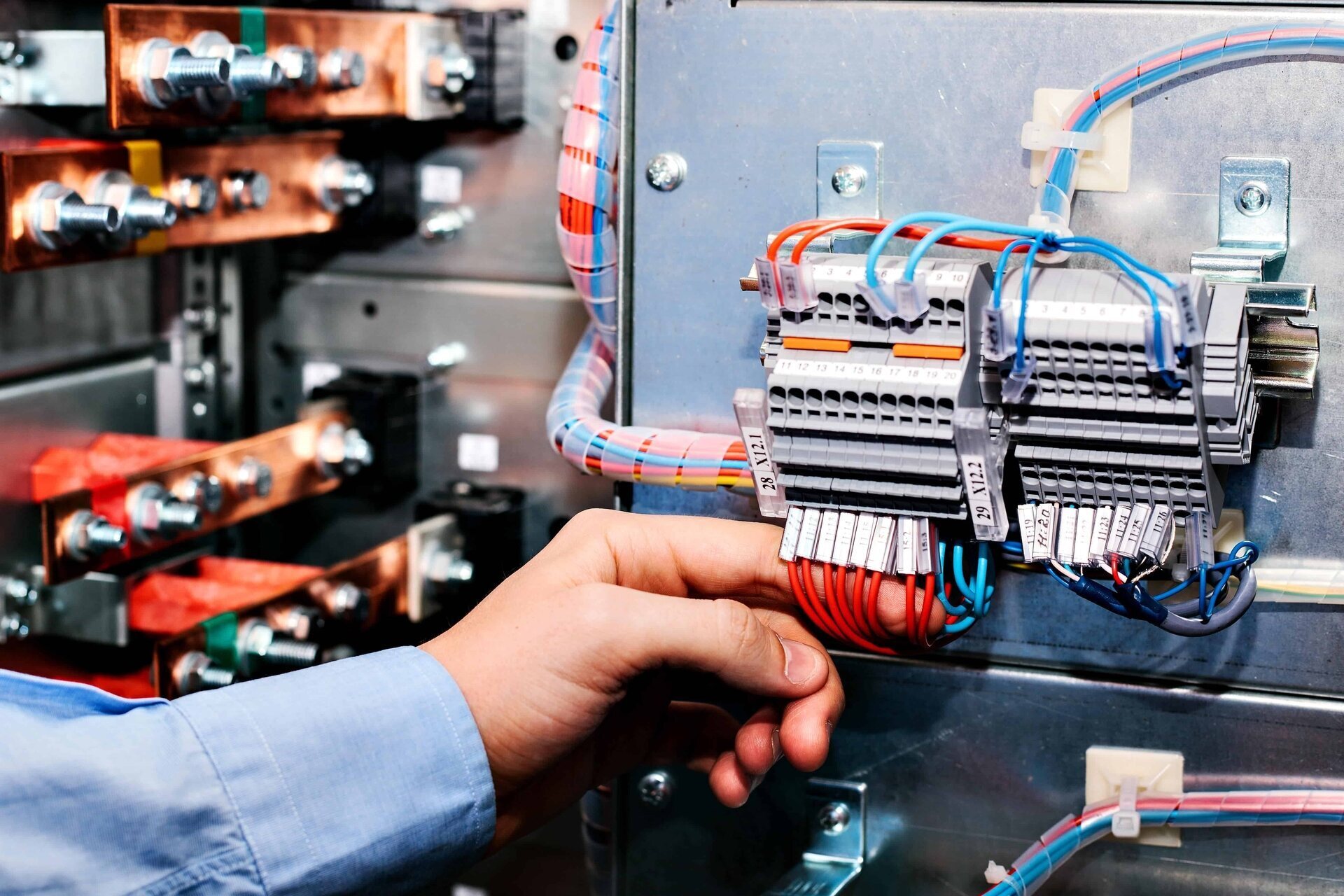

Conformity assessment procedure and CE marking for industrial process control systems in the concrete industry

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for complex control systems in the concrete industry. Through careful analysis of safety requirements according to EN ISO 13849-1, the required performance levels for safety functions can be verified. A particular challenge is the integration of various bus systems and interfaces according to EN 61131-3, where the functional safety of the entire system must be guaranteed at all times.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU,

Conformity assessment procedure and CE marking for automated assembly system in the plastics sector

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for automated assembly systems with rotary indexing table and multiple feeding stations. The integration of various safety concepts according to EN ISO 13849-1 to ensure personnel protection required a complex risk assessment according to EN ISO 12100. A particular challenge was the safe control of servo-controlled movement sequences on the rotary indexing table while complying with EN 60204-1.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU, 2011/65/EU,

Conformity assessment procedure and CE marking for packaging systems with cooling section

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for a packaging system for automatic closing and packaging of plastic closures. The particular challenge was securing the swivel conveyor mechanism according to EN ISO 13849-1 to ensure safe interaction between moving parts. Through consistent application of DIN EN 415-7 for collective packaging machines, all hazardous areas could be identified and secured with appropriate safety devices.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU, 2011/65/EU,

Conformity assessment procedure and CE marking for automated assembly systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for rotary assembly systems designed for precise joining of plastic components. Special attention was paid to functional safety according to EN ISO 13849-1. The integration of various safety devices such as dual-channel emergency stop systems and safety sensors on access doors presented a particular challenge, which was solved through a comprehensive safety concept according to EN ISO 12100.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for an integrated system for production and packaging of plastic caps

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for an integrated system consisting of an injection molding machine, linear robot and packaging system. The integration of safety functions according to EN ISO 13849-1 required special attention at the interfaces between the individual machines. A common emergency stop circuit according to EN ISO 13850 was implemented, ensuring that when an emergency stop switch is activated, all three machines stop safely. The complex risk assessment according to EN ISO 12100 considered all possible hazards in the transfer areas.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU, 2011/65/EU

Conformity assessment procedure and CE marking for ballasts/controllers for film and photo lighting

easyCE successfully supports the CE marking process up to the ready-to-sign Declaration of Conformity for specialized lighting system controllers. Electromagnetic compatibility according to EN 55015 and compliance with safety requirements per EN 61347-2-13 for DC power supplies of LED modules presented particular challenges. The overheating protection and secure power supply were validated through extensive testing according to EN 60598-1 to ensure the highest safety standards.

Considering: 2006/42/EG, 2014/30/EU, 2011/56/EU, 2014/35/EU, EN 13675:2010-10 etc.

Conformity assessment procedure and CE marking for decorative wooden lamps with electrical components

eeasyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for artisanal lamps made of natural wood with electrical components. During the assessment according to EN 60598-1 for luminaires, special attention was paid to the thermal load on the wooden body and the electrical safety of the integrated components. Safe insulation and strain relief of cables according to EN 60335-1, as well as correct labeling with power limitations, are crucial for compliance with safety requirements for decorative indoor lighting.

Considering: 2006/42/EG, 2014/30/EU, 2011/56/EU, 2014/35/EU, EN 13675:2010-10 etc.

Conformity assessment procedure and CE marking for testing equipment in industrial quality assurance

easyCE successfully supports the CE marking process up to the ready-to-sign Declaration of Conformity for a modular testing system for quality assurance. During the risk assessment according to EN ISO 12100, special attention was paid to electrical hazards and the safe isolation of energy sources. The integration of protective devices according to EN 60204-1 for electrical equipment and control systems presented a central challenge, which was successfully overcome through systematic testing and documentation of the safety functions.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for industrial evaporative cooling systems

easyCE successfully supports CE marking up to the ready-to-sign declaration of conformity for industrial cooling systems with water circulation and automated temperature control. When implementing the Machinery Directive 2006/42/EC, particular attention was paid to the electrical safety requirements according to EN 60204-1 and risk assessment according to EN ISO 12100. A particular challenge was the integration of the various control components for the water circuit and fan control while complying with the functional safety requirements according to EN ISO 13849-1.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for industrial welding systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for automated welding systems with integrated laser technology and fume extraction. The particular challenge was in evaluating the complex safety requirements according to EN ISO 13849-1 for the control systems and compliance with specific requirements for welding equipment according to EN 60974-1. The comprehensive risk analysis according to EN ISO 12100 particularly considered laser safety and the ergonomic design of the exchange station.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for electrical heating systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for heating systems with integrated temperature sensors and safety mechanisms. Compliance with the Low Voltage Directive and EN 61010-1 for safety of electrical measurement, control and laboratory equipment posed special requirements for technical documentation. A challenge was protecting against overheating using non-resettable thermal fuses according to IEC 60335-2-81, ensuring maximum operational safety.

Considering: 2014/35/EG, 2014/30/EU, 2011/56/EU,

Conformity assessment procedure and CE marking for data loggers in the photovoltaic sector

easyCE successfully supports the CE marking process up to the ready-to-sign declaration of conformity for a photovoltaic data logger with monitoring and control functions. During testing according to EN 62368-1 for electrical safety, all interfaces and expansion modules were tested for electromagnetic compatibility in accordance with EN 61000-6-3. A particular challenge was the conformity assessment of the various communication interfaces with different voltage levels.

Considering: 2014/35/EG, 2014/30/EU, 2011/56/EU,

Conformity assessment procedure and CE marking for scraper conveyor systems in the construction industry

easyCE successfully supports CE marking through to ready-to-sign Declaration of Conformity for scrapers for conveying dry or moist bulk materials. During risk assessment according to EN ISO 12100, special attention was paid to box access safety and interfaces for delivery vehicles. A particular challenge was the development of a safe request switch system that ensures personnel safety according to DIN EN 12629-1 without impairing economic operation.

Considering: 2006/42/EG, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for air-cooled condensers and dry coolers

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for V-shaped condensers and dry coolers with various refrigerant options. During risk assessment according to EN ISO 12100, special requirements for functional safety according to EN 60204-1 were considered. A particular challenge was securing the complex fan control systems and their accessibility while ensuring personnel protection, consistently implementing the requirements of EN ISO 13857 for guards and protective devices.

Considering: 2006/42/EG, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for LED lighting systems with remote control

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for modern RGB LED lighting systems with touch and remote control functions. The particular challenge was ensuring electromagnetic compatibility according to EN 55015 while utilizing remote control technology. Compliance with safety requirements according to EN 60598-1 for luminaires and EN 62368-1 for electronic equipment ensures reliable protection against electrical hazards with minimal power consumption.

Considering: 2014/35/EG, 2014/30/EU, 2011/65/EU

Conformity assessment procedure and CE marking for a motor test bench

easyCE successfully supports CE marking up to the ready-to-sign declaration of conformity for a test bench designed for testing and optimizing motor controls. The integration of safety components according to EN ISO 13849-1 presented a particular challenge, especially implementing the protective hood locking system and standstill monitoring at high speeds up to 8000 rpm. Through consistent application of EN 60204-1 for electrical equipment and EN ISO 12100 for risk assessment, a high level of safety was achieved that permits operation only when the protective hood is closed.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for garage formwork machines

easyCE successfully supports CE marking through to the ready-to-sign Declaration of Conformity for formwork systems used in concrete garage production. The particular challenges in this project were securing the hydraulic components and ensuring occupational safety when operating the large movable formwork elements. By applying EN ISO 13849-1, an appropriate performance level for the control system was achieved while simultaneously meeting the requirements of EN 60204-1 for electrical equipment.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU, 2011/65/EU

Conformity assessment procedure and CE marking for laser welding cabins with handheld laser devices

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for laser welding cabins with handheld laser welding systems. Particular challenges included compliance with laser protection requirements according to DIN EN 60825-4 and the safety design of the interlocking systems according to EN ISO 13849-1. The developed protection concept ensures reliable protection against dangerous laser radiation and prevents unintentional triggering of the laser outside the work area through intelligent sensor technology.

Considering: 2006/42/EG, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for veterinary cauterization devices

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for handheld cauterization devices. The implementation of requirements according to EN 60335-1 for electrical safety represents a central aspect. A particular challenge is compliance with electromagnetic compatibility according to the EMC Directive 2014/30/EU, which was solved through targeted measures such as shielding and interference suppression capacitors in accordance with EN 55014-1.

Considering: 2014/35/EU, 2014/30/EU, 2011/65/EU

Conformity assessment procedure and CE marking for automated cat litter cleaning devices

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for electronic household appliances for automated cleaning of cat litter. During the conformity assessment, special requirements for electrical safety according to EN 60335-1 and electromagnetic compatibility according to EN 55014-1 were considered. A particular challenge was securing the Wi-Fi interface against unauthorized access to ensure both data protection and operational safety of the device.

Considering: 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for electrothermal cutting tools

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for handheld cutting devices with thermal blades. The precise temperature control and user ergonomics were tested according to EN 60335-1 and meet all electrical safety requirements. A particular challenge was the combination of thermal risks and electrical safety, where specific protection mechanisms and insulation concepts according to EN ISO 12100 achieved a high level of protection.

Berücksichtigt u.a.: 2014/30/EU, 2011/65/EU, 2014/35/EU

Conformity assessment procedure and CE marking for solar parasol micro-inverter systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for innovative solar energy systems with integrated micro-inverters. Compliance with EMC requirements according to EN 61000-6-3 for residential emissions presented a particular challenge in this grid-connected system with WiFi functionality. Through careful testing of electrical safety according to EN 62109-1 and electromagnetic compatibility according to EN 61000-6-1, a high level of safety was ensured while maintaining optimal system performance.

Considering: 2014/35/EU, 2014/30/EU, 2014/53/EU

Conformity assessment procedure and CE marking for rope winding devices in recreational facilities

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for electrically operated rope winding devices. A special focus is placed on compliance with EN ISO 13849-1 for the functional safety of the drive system and EN 60204-1 for electrical equipment. The challenge was to develop a robust safety concept for outdoor use under changing weather conditions while ensuring a reliable emergency stop function in accordance with the requirements of the Machinery Directive.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for residual current transformers

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for residual current transformers used to detect fault currents. Integration into energy monitoring systems places special requirements on electrical safety according to EN 61010-1 and electromagnetic compatibility according to EN 61326-1. The assessment demonstrated secure insulation coordination according to IEC 60664-1 with test voltages up to 3 kV and suitability for industrial environments with pollution degree 3.

Considering: 2011/65/EU, 2014/35/EU

Conformity assessment procedure and CE marking for stationary battery energy storage systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for battery storage systems providing primary and secondary control power. The particular challenge was ensuring electromagnetic compatibility according to EN 61000-6-2 and compliance with electrical safety requirements per EN 62485-2. Through the integration of a highly effective fire detection system with dual detector dependency and automatic aerosol extinguishing, a comprehensive safety concept was implemented.

Considering: 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for hydraulic CNC press brakes

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for hydraulic servo CNC press brakes. The risk assessment according to EN ISO 12100 identifies all potential hazard points in the working area between upper and lower beam. A particular challenge was implementing a multi-layered safety concept with optical safety systems according to EN ISO 13849-1, which offers maximum protection without restricting productivity during precise bending of complex workpieces.

Considering: 2006/42/EG, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for a universal machine for manufacturing automotive interior parts

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for servo-hydraulic universal machines for manufacturing interior parts. The integration of multiple processes such as pressing, punching and edge folding in one system presented special requirements for risk assessment according to EN ISO 12100. By implementing modern control safety measures in accordance with EN 60204-1 and EN ISO 13849-1, the functional safety of the complex hydraulic and electrical systems could be demonstrably ensured.

Considering: 2006/42/EG, 2014/30/EU, 2014/35/EU

Conformity assessment procedure and CE marking for water treatment systems

easyCE successfully supports CE marking up to the signature-ready Declaration of Conformity for modern water filtration and treatment systems with integrated electronic controls. Compliance with electromagnetic compatibility according to EN 61000-6-3 and electrical safety according to EN 60335-1 presented particular challenges. Through targeted testing and technical adaptations, the requirements for aqua-stop safety mechanisms as well as the isolation of the UV lamp and pump control according to EN 60335-2-41 could be fully met.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for ballasts/controllers for film and photo lighting

easyCE successfully supports the CE marking process up to the ready-to-sign Declaration of Conformity for specialized lighting system controllers. Electromagnetic compatibility according to EN 55015 and compliance with safety requirements per EN 61347-2-13 for DC power supplies of LED modules presented particular challenges. The overheating protection and secure power supply were validated through extensive testing according to EN 60598-1 to ensure the highest safety standards.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for decorative wooden lamps with electrical components

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for artisanal lamps made of natural wood with electrical components. During the assessment according to EN 60598-1 for luminaires, special attention was paid to the thermal load on the wooden body and the electrical safety of the integrated components. Safe insulation and strain relief of cables according to EN 60335-1, as well as correct labeling with power limitations, are crucial for compliance with safety requirements for decorative indoor lighting.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for water filtration systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for water filtration systems with multiple filtration stages and UV sterilization. The multi-stage design with pollutant filtration, molecular filtration and UVC disinfection according to EN 60335-1 places special demands on electrical safety and reliability. The integration of pressure monitoring sensors, non-return valves and automatic shutdown functions in accordance with EN ISO 13077 ensures maximum operational safety in drinking water treatment.

Considering: 2014/35/EU

Conformity assessment procedure and CE marking for data loggers in the photovoltaic sector

easyCE successfully supports the CE marking process up to the ready-to-sign declaration of conformity for a photovoltaic data logger with monitoring and control functions. During testing according to EN 62368-1 for electrical safety, all interfaces and expansion modules were tested for electromagnetic compatibility in accordance with EN 61000-6-3. A particular challenge was the conformity assessment of the various communication interfaces with different voltage levels.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for fire extinguisher training equipment

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for filling stations with automatic pump systems. The particular challenge lies in ensuring electrical safety according to EN 60204-1 while simultaneously pressurizing training equipment. Through careful application of EN ISO 13849-1 for control systems, an appropriate performance level was achieved that guarantees safe operation even during intensive use.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for high-voltage measuring adapters

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for a measuring adapter designed for safely conducting measurements on high-voltage systems in electric vehicles. During the safety analysis according to EN ISO 12100, special attention was given to the double insulation and the serial 100 kOhm line resistors that protect against electric shock. Compliance with EN 61010-31 for measurement category CAT III at voltages up to 1000V DC represented a central challenge.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for conventional lathes

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for precision metal processing machines. During risk assessment according to EN ISO 12100, the specific requirements for control elements and protective devices were identified to ensure safe operation. Implementing the machine-specific safety requirements according to EN ISO 23125 presented a particular challenge, especially regarding moving parts and drive elements.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Conformity assessment procedure and CE marking for motorized awning systems

easyCE successfully supports CE marking up to the ready-to-sign Declaration of Conformity for cassette awnings with motorized drives. The integration of modern sensors for automatic retraction during wind required special attention during risk assessment according to EN ISO 12100. The reliable protection against electric shock according to EN 60335-2-97 and compliance with wind load resistance requirements as per EN 13561 were comprehensively verified and documented.

Considering: 2011/65/EU, 2014/35/EU, 2014/30/EU

Get CE-marking done in 3 simple steps

Step 1

Request expert opinion

Ask for our expert opinion free of charge and find out what is necessary for the CE marking of your product. Be prepared to describe your product in broad terms.

Step 2

Receive our offer

If your product is subject to CE marking, we offer you our support with the CE marking and all accompanying measures. We will be happy to explain necessary steps on the phone.

Step 3

We get it done

When you place an order, you will be assigned your own personal CE expert who will carry out your CE marking and accompany you throughout the entire process. Your expert will also be at your side after the CE marking has been successfully completed.

Get CE-marking done, worry-free

Trust the experts of product safety and conformity

Willy Lebherz - Founder and Managing Director of easyCE

- Expert in product safety and conformity since 1995

- Recipient of the "Medal of the Order of Merit of the Federal Republic of Germany", awarded in 1983 by the then Federal President Carl Carstens

- Master of measurement and control technology

- Captain (ret.), Project Officer for Technical Logistics in the Army Material Office and Chief of the Telecommunications Repair Company

easyCE is a digital, dynamic engineering office with a focus on product safety and product conformity - especially CE-marking. We support manufacturers, operators and dealers in designing products safely and offering them on the market in compliance. We are a "full-service provider" and can take over the entire conformity assessment process for you if you wish. To do this, we support you in carrying out risk assessments, researching standards, product analyses, developing suitable safety precautions, preparing user-friendly technical documentation, coordinating tests and all other accompanying measures. easyCE was founded in southern Germany, but is now active globally.

We know what you need to do to get CE-marking done, worry-free.